Platform Solutions

Platform mounted systems consist of a number of communications or power elements, mounted on a transportable skid platform, each element installed in an environmentally protected enclosure. Platform solutions are often utilized when the installed equipment is normally designed for outdoor installation and the platform serves as an integration base. Outdoor equipment racks can also be used to house system electronics on the platform. With properly designed cooling, platform systems can reduce operating costs as compared to shelters in similar applications.

Applications & Standard Features

Platform solutions are ideal for projects with tight timelines. These turn-key operational shelters can be integrated quickly and efficiently. Additionally, they provide the durability of VFP’s engineered structure with the architecture to house open air electronic components that can be easily added to or upgraded. Target applications for platform solutions include small cell sites, solar farm distributed power equipment, disaster recovery communications, and military theater systems.

Configuration

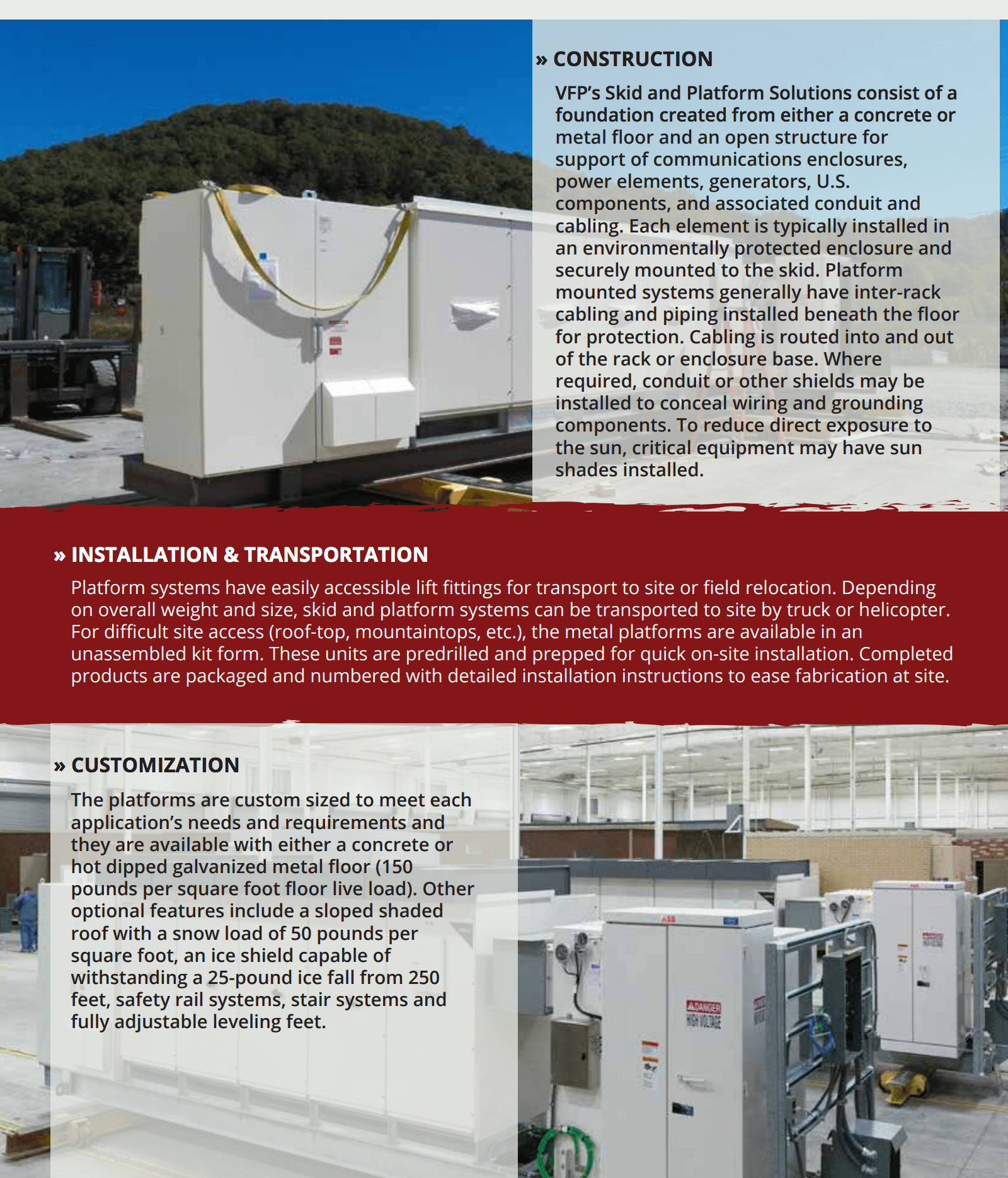

VFP’s Platform Solutions consist of a skid with either a concrete or metal floor and an open structure for support of communications enclosures, power elements, generators, US components, and associated conduit and cabling. Each element is typically installed in an environmentally protected enclosure. Platform mounted systems generally have inter-rack cabling and piping installed beneath the floor for protection. Cabling is routed into and out of the rack or enclosure base. Where required, conduit or other shields may be installed to conceal wiring and grounding components. To reduce direct exposure to the sun, critical equipment may have sun shades installed.

Transportation & Installation

Platform systems have easily accessible lift fittings for transport to site or field relocation. Depending on overall weight and size, platform systems can be transported to site by truck or helicopter.

For difficult site access (roof-top, mountaintops, etc.), the metal platforms are available in an unassembled kit form. These units are predrilled and prepped for quick on-site installation. Completed products are packaged and numbered with detailed installation instructions to ease fabrication at site.

Standard & Custom Features

The platforms are custom sized to meet your application needs and available with either a concrete or hot dipped galvanized metal floor (150 pounds per square foot floor live load, 150 miles per hour wind load). Other optional features include a sloped shaded roof with a snow load of 50 pounds per square foot, an ice shield capable of withstanding a 25 pound ice fall from 250 feet, safety rail systems, stair systems and fully adjustable leveling feet.