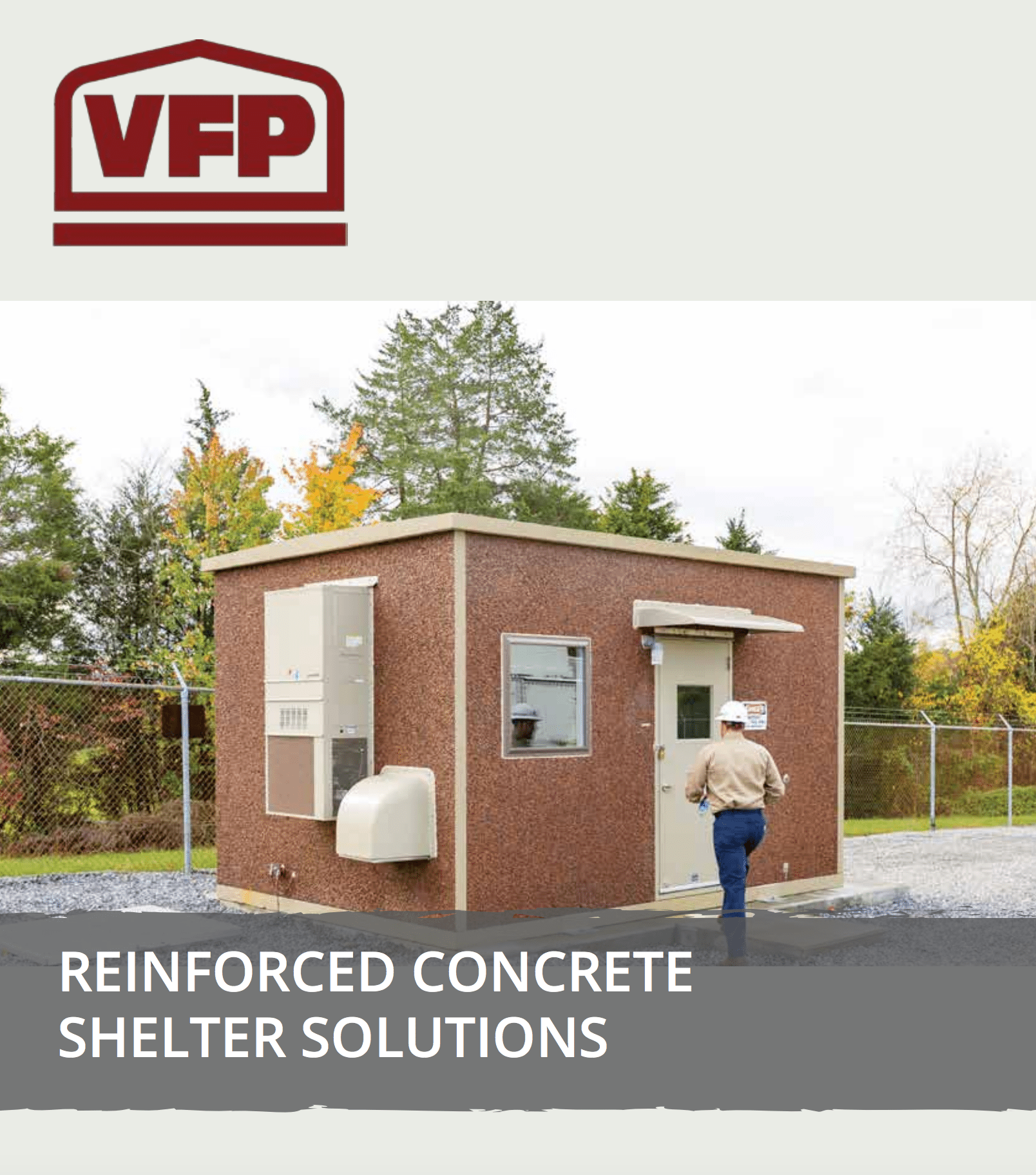

Concrete Shelter Solutions

From the Arabian desert to the arctic, VFP fully integrated equipment shelters are the answer to difficult locations and harsh environments, and have set the industry standard for workmanship and product quality for over 50 years.

Application

Concrete shelters are used across a broad spectrum of markets. The flexibility of design and the inherent security of concrete protect your critical systems wherever they go. Cellular telephone, police, fire and emergency medical service radio systems, and utility control houses are but some of the many applications VFP Industries concrete shelters are serving.

Construction

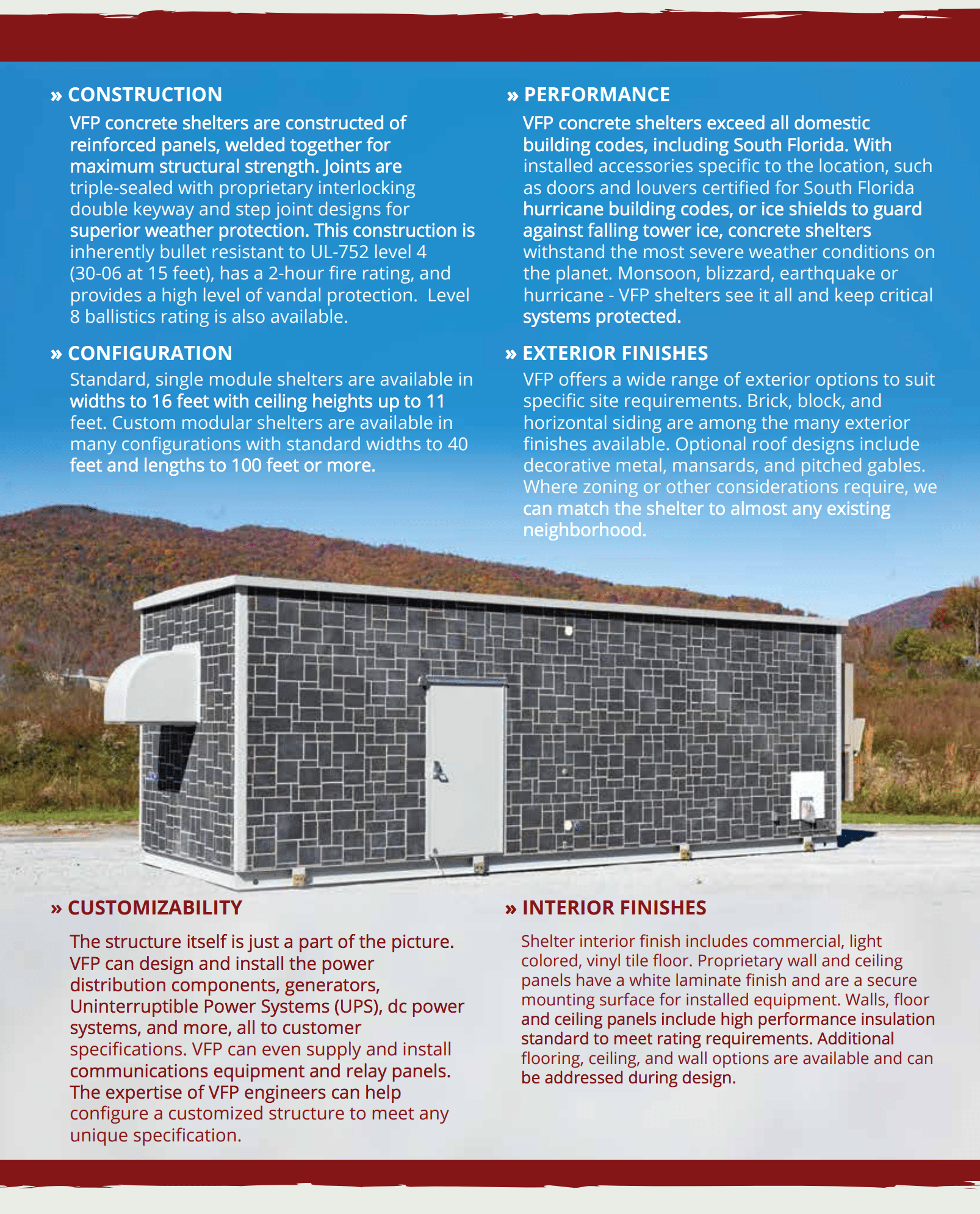

VFP concrete shelters are constructed of reinforced panels, welded together for maximum structural strength. Joints are double-sealed with proprietary interlocking double keyway and step joint designs for superior weather protection. This construction is inherently bullet resistant to UL-752 level 4 (30-06 at 15 feet), has a 2-hour fire rating, and provides a high level of vandal protection. The complete shelter, as delivered by VFP, will include all required state inspections and certifications. Only the on-site installation and interconnection to site facilities will be subject to local building inspection and approval.

Configuration

Standard, single module shelters are available in widths to 16 feet with ceiling heights to 9 feet or more. Custom modular shelters are available in many configurations with standard widths to 40 feet and lengths to 100 feet or more. VFP Industries Field Service personnel provide world-wide, on-site assembly of modular shelters as well as installation and setup for all our products.

Exterior Finishes

In addition to the standard exterior finishes shown, VFP offers a wide range of options to suit specific site requirements. Brick, block, and horizontal siding are among the many exterior finishes available. Optional roof designs include decorative metal, mansards, and pitched gables. Where zoning or other considerations require, we can match the shelter to almost any existing neighborhood.

Pitched Roof

The roof section is constructed of minimum 4 inch (10 cm) thick reinforced concrete, sloped from the center to allow water runoff. The exterior of the roof is covered with an ultraviolet resistant, reflective elastomeric coating which can help to reduce energy consumption and prevent water intrusion.

The roof section as a whole fits as a "cap" over the shelter walls leaving no exposed roof-to-wall joints and additionally eliminating the possibility of water intrusion into the shelter.

The ceiling is sheathed with a composite panel that includes high performance insulation. The panel is then covered with an aesthetically pleasing white laminate.

Foundation

Foundation requirements vary with the local terrain and soil conditions. The VFP concrete shelter has been designed for installation on a variety of foundations that include concrete slabs, compacted gravel, piers, and perimeter grade beams.

VFP will provide a suggested anchor location, but the site designer is cautioned that all foundations must be evaluated in consideration of local soil conditions, seismic requirements, and local building restrictions.

Wall

The standard wall is constructed of four-inch (10 cm) thick reinforced concrete. Each wall is constructed using a two-step keyway joint. This keyway joint is part of our double-sealed wall-to-wall construction, eliminating the possibility of water intrusion into the shelter.

Typically, the shelter is sheathed with a composite wall panel that includes high performance insulation. The white color allows maximum utilization of available light. The interior panel also supports electrical and mechanical wall mounted components and provides a convenient structural surface to mount additional components on site.

Insulation

The walls and roof are insulated with high performance insulation that provides a thermal value of R-11. The floor section is insulated using a polystyrene insulation.

VFP concrete shelters are engineered to restrict the possibility of moisture intrusion. Not only do we recess the floor-to-wall joint and provide a keyway, wall-to-wall connection, we also apply to the roof a UV-resistant elastomeric coating which will not crack, peel or flake.

All exterior air intake and exhaust openings are fitted with color matched weather hoods. VFP installed equipment and conduits that penetrate the shelter walls will be sealed with urethane caulk.

Interior Components

VFP provides a wide variety of pre-wired and pre-installed interior components. These include lights, convenience receptacles, power distribution, HVAC systems, UPS systems, and generators. Visit our quote request page for detailed options.

Exterior Finishes

The standard exterior is an aesthetically pleasing exposed aggregate finish. A clear coat sealer is applied to the stone exterior which provides UV protection and enhances the color of the stone. Optional finishes are available to meet specific applications.

Floor

The floor is six-inch (15 cm) thick precast reinforced concrete, insulated and equipped with integral lifting points.

VFP's unique floor section is constructed with a recessed step-joint. This step-joint, which is part of our triple sealed floor-to-wall construction, eliminates any possibility of water intrusion into the shelter. The interior floor is covered with a high quality commercial grade light color vinyl tile.

Additional flooring options are available upon request.

Interior Finishes

Shelter interior finish includes commercial, light colored, vinyl tile floors. Proprietary wall and ceiling panels have a white laminate finish and are a secure mounting surface for installed equipment. Walls, floor and ceiling panels include high performance insulation with an overall R-11 thermal rating. Additional flooring, ceiling, and wall options are available and can be addressed prior to assembly.

Specifications

The structure itself is just a part of the picture. VFP can design and install the power distribution components, generators, Uninterruptible Power Systems (UPS), dc power systems, HVAC equipment, lighting, alarms, grounding, and more, all to customer specifications. In fact, VFP can even supply and install the communications equipment, relay racks, and customer-furnished equipment (CFE) as well. Tap into the expertise of VFP engineers to help configure your unique specifications.

Performance

Protecting your critical equipment and maintaining its operating environment are critical to maximizing system availability. VFP concrete shelters meet that challenge, exceeding all domestic building codes, including South Florida. With installed accessories specific to the location, such as doors and louvers certified for South Florida hurricane building codes, or ice shields to guard against falling tower ice, concrete shelters withstand the most severe weather conditions on the planet. Monsoon, blizzard, earthquake or hurricane - VFP shelters see it all and keep critical systems protected.

Installation

Delivery of completed shelters will be coordinated by VFP Transportation, including all over-the-road permitting and on-site crane. The shelter floor incorporates integral lifting points for ease of off-loading and placement on the foundation. This allows shelters to be installed on a variety of foundations to suit the particular site and application. Piers, concrete slabs, grade beams and steel frames are common, but others designs are possible. Although VFP provides suggested anchor locations and mounting details, the final foundation design is the responsibility of the site development engineer and must take into consideration the soil conditions, seismic requirements, support structure characteristics, and local building codes.